Loading...

Hammer Lug Unions

HAMMER LUG unions (WECO couplings) allow for quick connecting the pipelines and flexible hose assemblies in the oil and gas industry. They are popularly used on drilling rigs to transfer petroleum, gas, mud, cement, water, air etc.

A HAMMER LUG union is assembled from a male and female component which is welded to pipework. The male and female components are fastened together with a threaded wing nut. A threaded wing nut secures the male and female components together. The nut is made up of three lugs that can be tightened with a hammer. The union's design allows for fast pipe assembly and disassembly, which is critical for mobile rigs operating in harsh environments.

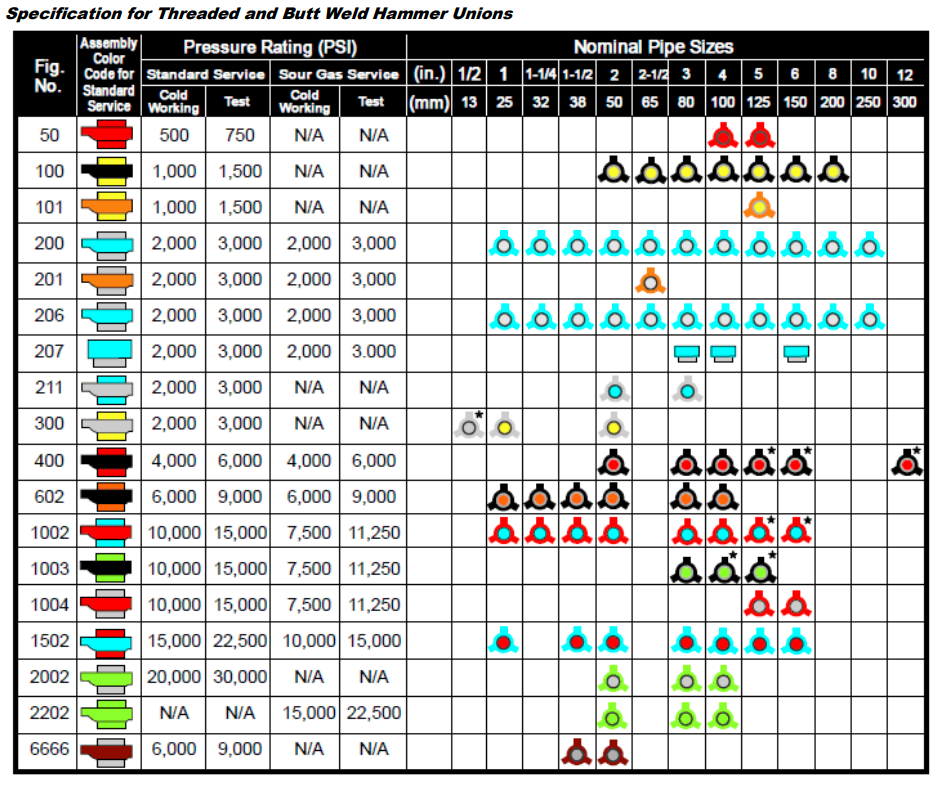

HAMMER LUG unions are designated with numbers (Figures) corresponding to particular types. Each figure, regardless of size, is designed for a specific working pressure and application, and the union's components are painted with a specific color to aid identification. AAR International offers a wide variety of traditional and sour gas hammer unions. Each union is inspected thoroughly to ensure long-term, dependable operation in all weather conditions. We offer HAMMER LUG unions in sizes ranging from ½’’ to 12’’, with cold working pressures ranging from 500 to 20,000 psi (depending on the type of the union).

Hammer Seal Unions

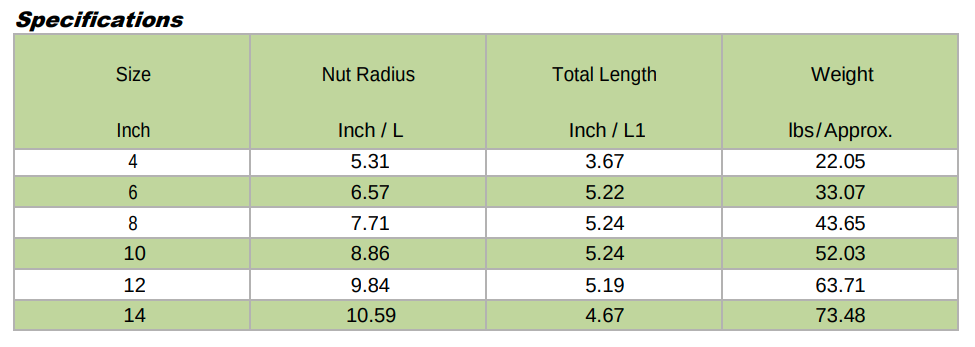

Hammer Seal Unions are designed to join drilling mud tanks quickly and without leaks. The external threaded male portion of the Union welds to a pipe stub at the tank wall. A smaller O.D. connecting pipe extends though the female portion, the O-ring, and then the male portion of the union. When the internally threaded female component is tightened onto the male component, the o-ring between the components is squeezed to an oblong cross-section. The O-ring then seals against the O.D. of the connecting pipe. Hammer seal Unions are offered in sizes 4" through 14".

Tank Unions accept up to 7 degrees of pipe misalignment. The female sub of the hammer seal union welds to a schedule 40 / 80 pipe. Nitrile O-ring provides a compressive non leak seal that limits the line fluid pressure to 150 PSI.